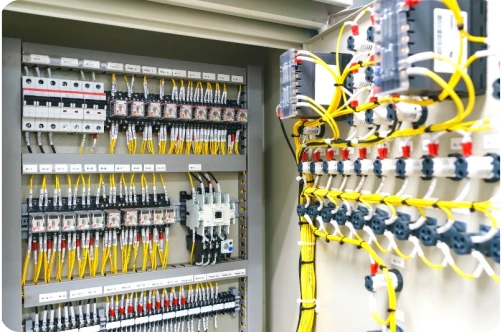

A Main Distribution Board (MDB) is an electrical panel or enclosure that houses essential protective and control devices such as fuses, circuit breakers, and earth leakage protection units. It receives electrical power from a transformer or an upstream panel and distributes it to various individual circuits or consumer points.

An MDB typically features one or more incoming power sources and incorporates main circuit breakers along with residual current or earth leakage protection devices. The structure consists of a free-standing enclosure, a busbar system, molded case circuit breakers (MCCBs), metering and support equipment, and the necessary current transformers (CTs).

Panels within the MDB are organized systematically into sections, generally comprising an incomer section and one or more outgoing sections, ensuring safe and efficient power distribution.

An SMDB (Sub Main Distribution Board) is fed by the MDB and is typically installed at the point where a large distribution cable terminates and multiple smaller sub-circuits begin. While similar in construction to final distribution boards, SMDBs are generally larger and are positioned midway in the electrical distribution system.

Their primary role is to serve as an intermediate distribution point, dividing the electrical load from the MDB into several smaller circuits, ensuring efficient and organized power distribution across different zones or sections of a facility.

“A Final Distribution Boards(FDB) is fed by the SMDB. Each Final Distribution Board then further divides and controls the electrical supply, delivering it to individual circuits and end-user equipment such as lighting, sockets, and appliances. This structured hierarchy ensures efficient, safe, and organized distribution of electrical power throughout the facility.”

Capacitor banks are used to improve the power factor by introducing capacitive reactance into the system in a controlled, step-wise manner, based on real-time reactive power demand.

A power factor controller continuously monitors the electrical load and power factor on the Low Voltage (LV) Panel. It automatically switches the capacitor steps on or off to maintain the system power factor at a predefined optimal level. This dynamic correction of lagging reactive power (VAR) not only enhances the quality of power delivered across the distribution network but also results in reduced energy losses and lower electricity charges for the end user. Capacitor banks offer a dependable and efficient solution for maintaining power quality and system efficiency

Changeover Panels are electrical switching systems that allow seamless transfer of power supply between two sources—typically from the main utility (grid) supply to a backup generator or alternative power source. These panels ensure uninterrupted power by automatically or manually switching to the standby source during a power failure and back to the main supply when it is restored. They are essential for maintaining continuous operation in critical facilities such as hospitals, data centers, and industrial plants.

Generator Synchronizing Panels are control panels used to synchronize two or more generators with each other or with the utility grid. These panels monitor voltage, frequency, and phase angle to ensure all sources are matched before connecting them together. The synchronization process allows multiple generators to share the load efficiently, ensuring balanced power distribution and system stability. These panels are commonly used in applications requiring high reliability and scalability, such as large industrial installations and power plants.

Lighting Control Panels are electrical panels designed to manage, control, and distribute power to lighting circuits within a building or facility. These panels allow centralized or automated control of lighting systems, enabling switching, dimming, scheduling, and zoning of lights for energy efficiency, convenience, and safety.

They can be integrated with sensors (e.g., occupancy or daylight sensors), timers, or building management systems (BMS) to optimize lighting based on usage patterns and environmental conditions. Lighting control panels are commonly used in commercial buildings, industrial facilities, malls, offices, and public infrastructure to provide flexible and efficient lighting solutions.

Power Monitoring Panels are specialized electrical panels designed to continuously measure and record key electrical parameters—such as voltage, current, power, energy consumption, frequency, and power factor—within an electrical distribution system. These panels help in real-time monitoring, analysis, and optimization of electrical energy usage, enabling improved efficiency, load management, and fault detection.

A Battery Circuit Breaker Panel (BCBP) is a specialized electrical panel designed to protect and control the DC power distribution from a battery bank to various connected loads or systems. It houses DC-rated circuit breakers that serve as protective devices, isolating faults such as overcurrents, short circuits, and enabling safe maintenance and emergency shutdowns.

Motor Control Center Panels are electrical panels designed to control, protect, and manage multiple motors from a central location. They typically include motor starters, circuit breakers, relays, contactors, and other devices arranged in sections, allowing operators to start, stop, and monitor motors safely and efficiently. MCCs can integrate different starter types such as VFDs for precise speed control and energy savings, Soft Starters for reduced inrush current, DOL starters for smaller motors, Star-Delta starters for large motors, Two-Speed starters for dual-speed operation, and Reversible starters for forward and reverse control. Widely used in manufacturing plants, HVAC systems, water treatment facilities, and pumping stations, MCC panels provide centralized management and reliable operation of multiple motors within industrial and commercial environments.